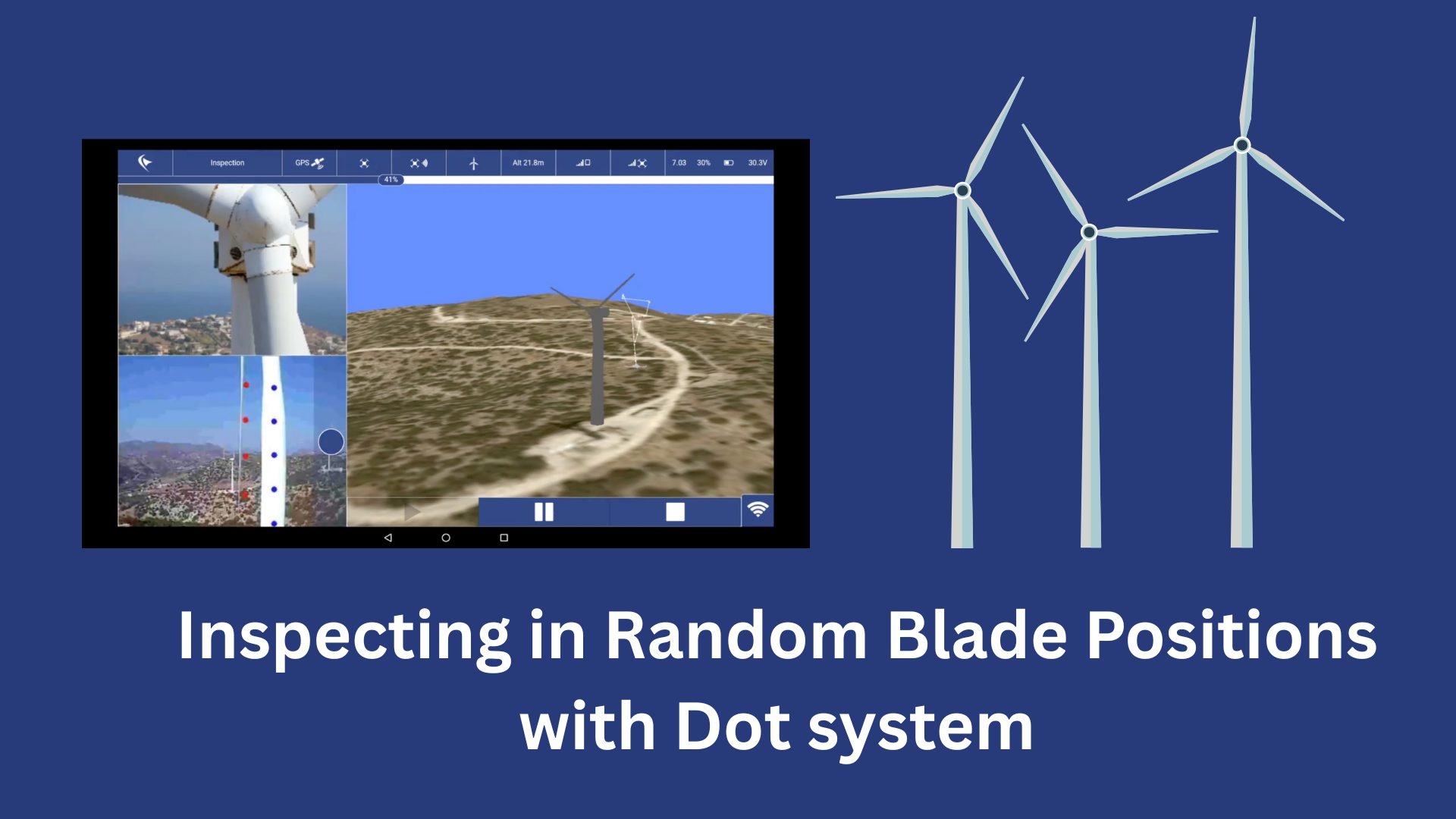

Inspecting in Random Blade Positions

🚀 A few weeks ago our team completed 56 wind turbine inspections in UK under some very unique conditions.

🪫 The site was on planned downtime with no power, meaning turbines were locked in random blade positions. With Dot technology, we successfully inspected turbines stopped in those random angles, while keeping a high quality and perpendicularity and, what is most important, without the client losing a single unit of generation.

For those not aware, most drone inspections require that the turbine is stopped with one blade up (12 o’clock position) and this can only be done if the wind farm is energised and blades can be positioned.

As far as we know, high quality-inspecting in any position isn’t possible with some other solutions in the market.

Dot’s flexibility allows inspections to be carried out during low wind conditions, when blade re-positioning is challenging, or during planned substation downtimes. This avoids additional downtime solely for inspections, saving both time and money.

This project is a great example of how flexibility, the right tools, and innovative thinking can make the difference for wind operators.