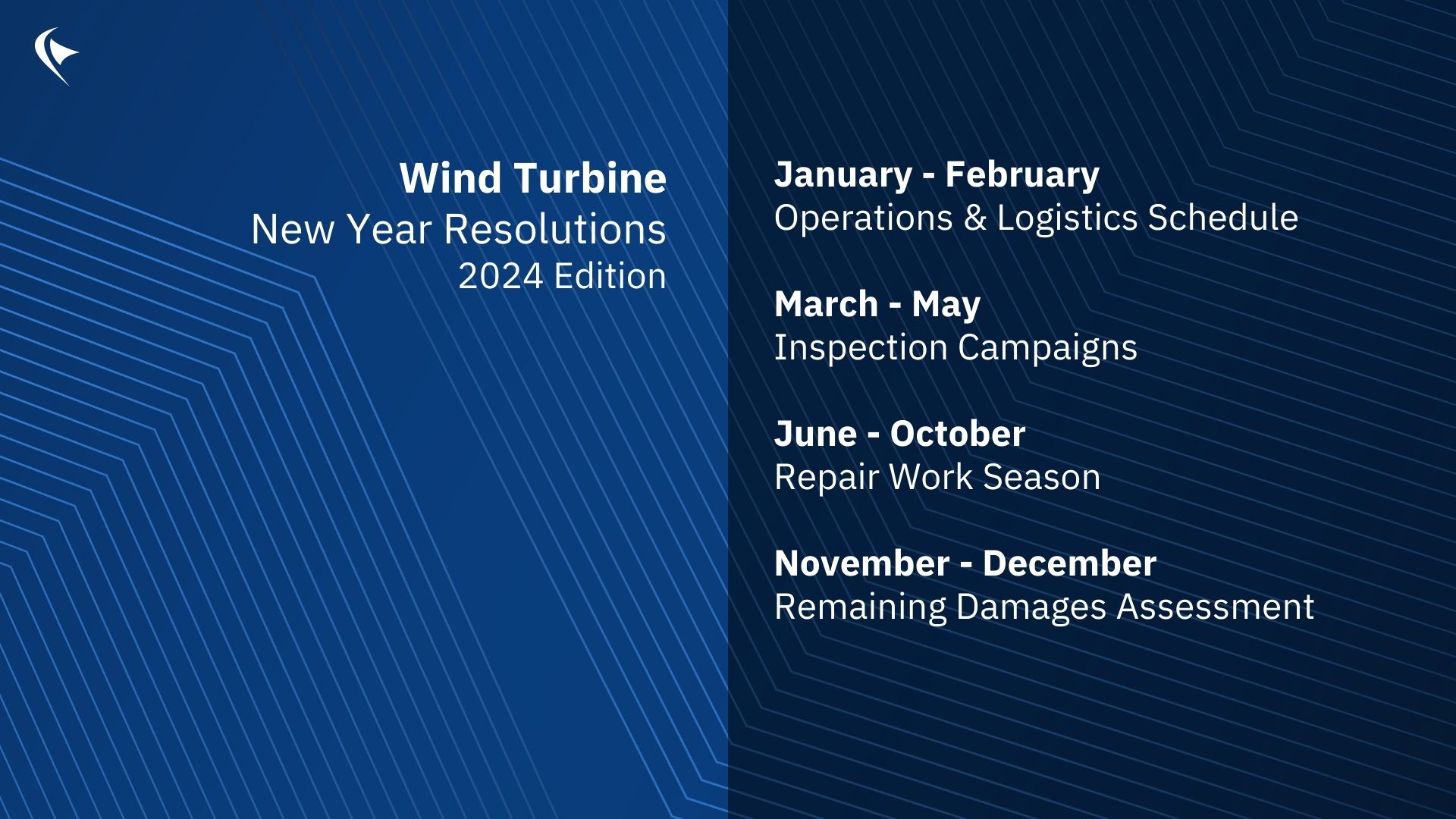

Wind Turbine New Year Resolutions | 2024 Edition

It’s that time of year when we all draft our New Year resolutions. Sadly, turbine blades cannot do that for themselves but in a world where they were able to, we imagine they would look like this:

- January – February: Operations & Logistics Schedule

- March – May: Inspection Campaigns

- June – October: Repair Work Season

- November – December: Remaining Damages Assessment

Time is of the essence as some damages propagate faster than others depending on location and weather conditions. Planning inspections and repair work on time is important to keep blades healthy and prevent energy production losses. High unexpected maintenance costs are every owner/operator’s nightmare for a reason and we are on a mission to help you:

- Save time and budget by inspecting autonomously

- Get accurate damage reports that you can then use to review the status of your fleet

- Create data-driven repair work orders

💡Pro tip: We suggest starting inspections as early as February to allow more time for repairs especially for category 4 and 5 damages which require longer turbine downtime. Your wind turbines and bank account will be grateful!

#windenergy #blades #bladerepair #droneinspection #UAV #perceptualrobotics #robotics #artificialintelligence #renewableenergy #innovation #drone #energy #offshorewind #offshorewindenergy #operations